Need a Lyophilizer? Read this before you buy

Lyophilization, or freeze drying is commonly used in many labs as a solution for long term storage or as a sample prep step. This article will help you determine the best freeze dry system for your needs.

Lyophilization, or freeze drying is commonly used in many labs as a solution for long term storage or as a sample prep step. This article will help you determine the best freeze dry system for your needs.

In choosing the correct lyophilizer, consider the following:

1) What is the total amount of moisture (in liters) that you wish to remove?

For example, if you are running tissue samples, the liquid volume will be small, 500mls or less. Labconco

FreeZone Freeze Dry Systems handle half of the total ice holding capacity. As an example, a 6L freeze dryer will be able to process about 3 liters total. If you put 6L on the freeze dryer, you could overload it resulting in poor vacuum, increase in collector temperature and low recovery of the solvent on the coils.

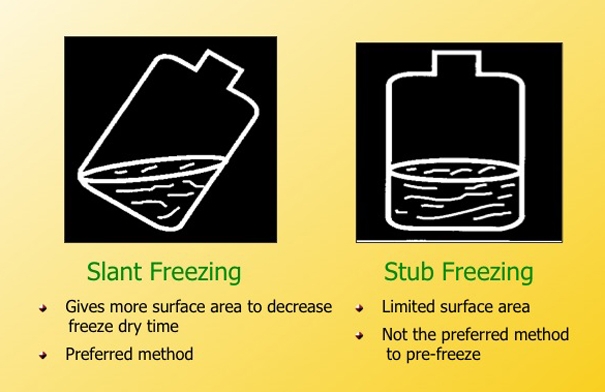

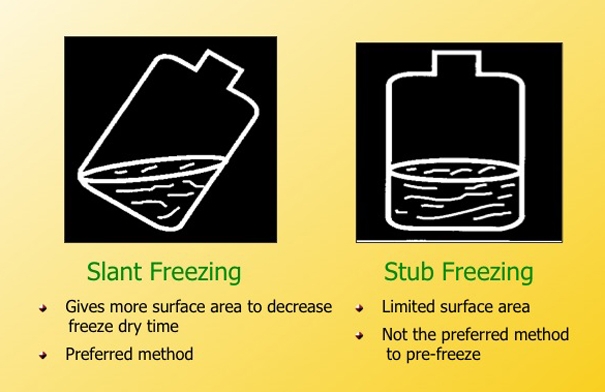

When determining the rate of lyophilization, the liter per 24 hour rating is for shell frozen water. Samples that are slant frozen, or stub frozen, will have slower sublimation rates. A thinner shell frozen sample will also be faster than a thick sample. Freeze dried samples dry from top to bottom. Sample at the bottom of the flask or vial needs to move through the dried layer, which takes longer to lyophilize.

2) What type of sample are you processing?

Each component is important, so think about all of the solvents and solutes that will be a part of the total samples. In order to freeze dry properly and protect the vacuum pump, a temperature differential of 15–20˚ between the samples' freezing point and the collector chamber is required. If the collector isn't cold enough, the samples will bypass the collector and enter the vacuum pump causing damage.

In protein or HPLC samples, Acetonitrile and TFA are the typical solvents. Acetonitrile has a eutectic temperature, or freezing point, of -42˚C. Because of this, a standard -50˚C collector is not cold enough to trap the solvent. A cascade -84˚C model is required to freeze dry and effectively trap the solvents.

For fruit samples, sugars can lower the samples' eutectic temperature. If the samples are sea water, the salt can cause damage to the stainless steel and lower the freezing point. Below are some recommendations.

Freezing points of solvents and collector recommendation

|

Solvent |

Freezing point °C |

Collector required |

Additional notes |

|

Acetone |

-94.3 |

-105C |

Must be diluted to 15% Acetone |

|

Acetonitrile |

-42 |

-84C Cascade |

|

|

Acetic Acid |

16.6 |

-50C |

|

|

Chloroform |

-63.5 |

-84C |

|

|

DMSO |

18.5 |

-50C |

DMSO can be difficult to freeze dry |

|

Ethanol |

-117.3 |

-105C |

Must be diluted to 15% ethanol |

|

Hexane |

-95 |

-105C |

Must be diluted to 15% hexane |

|

Methanol |

-97.8 |

-105C |

Must be diluted to 15% methanol |

|

Methylene Chloride |

-97 |

-105C |

Must be diluted to 15% methylene chloride |

|

Salt water |

Varies on PPM |

-84C Cascade |

PTFE-coated chamber recommended |

|

Water |

0 |

-50C |

|

If samples are acidic or can cause damage to the stainless steel coils, PTFE coating is recommended to prevent rust and holes in the collector.

3) What format are your samples in—Vials, bulk trays, flasks, tubes, etc.?

Make sure your accessories match up with the format of your samples. If you need to stopper under vacuum, a stoppering tray dryer is required. If you have test tubes that you’d like to place in a flask test tube holders are available. There are many accessories to customize a freeze dryer to your specific needs.

4) Have you considered the vacuum pump?

A

vacuum pump is always required. For standard aqueous based samples, a general rotary vane pump will work. For acids or solvents, a hybrid type pump would be recommended. Make sure the pump meets the minimum specifications required for your lyophilizer.

Have a question? Labconco is here to help. Contact me right now!

You may also be interested in: Top 5 mistakes made in the lyophilization process

You may also be interested in: Top 5 mistakes made in the lyophilization process

Lyophilization, or freeze drying is commonly used in many labs as a solution for long term storage or as a sample prep step. This article will help you determine the best freeze dry system for your needs.

Lyophilization, or freeze drying is commonly used in many labs as a solution for long term storage or as a sample prep step. This article will help you determine the best freeze dry system for your needs. You may also be interested in: Top 5 mistakes made in the lyophilization process

Having trouble choosing the right accessories for your freeze dry process? Optimizing the freeze dry process-What accessories are right for you?