Optimizing the freeze dry process: What accessories are right for you?

Determining the right accessories for your freeze dryer is essential for the freeze dry process. Samples can range from a few microliters in 96-well plates to large bulk type samples on trays. In order to determine the best accessories for your needs, you have to determine your sample size and the format you want to use.

Freeze dry flasks vary in size from 25mls up to 2L. When using a flask, samples can go directly into the flask or test tubes can be placed in the flasks using optional test tube holders. If the samples go directly into the flasks, they shouldn’t be filled more than 1/3 to ½ full of the flask's capacity. For maximum surface are, we recommend shell or slant freezing the samples.

Two methods are available to shell freeze. A mechanical shell freezer uses rotating cold fingers in a heat transfer solution to give a uniform shell frozen sample. The manual method uses a dry ice solution and manual rotation of the flask until the sample is completely frozen.

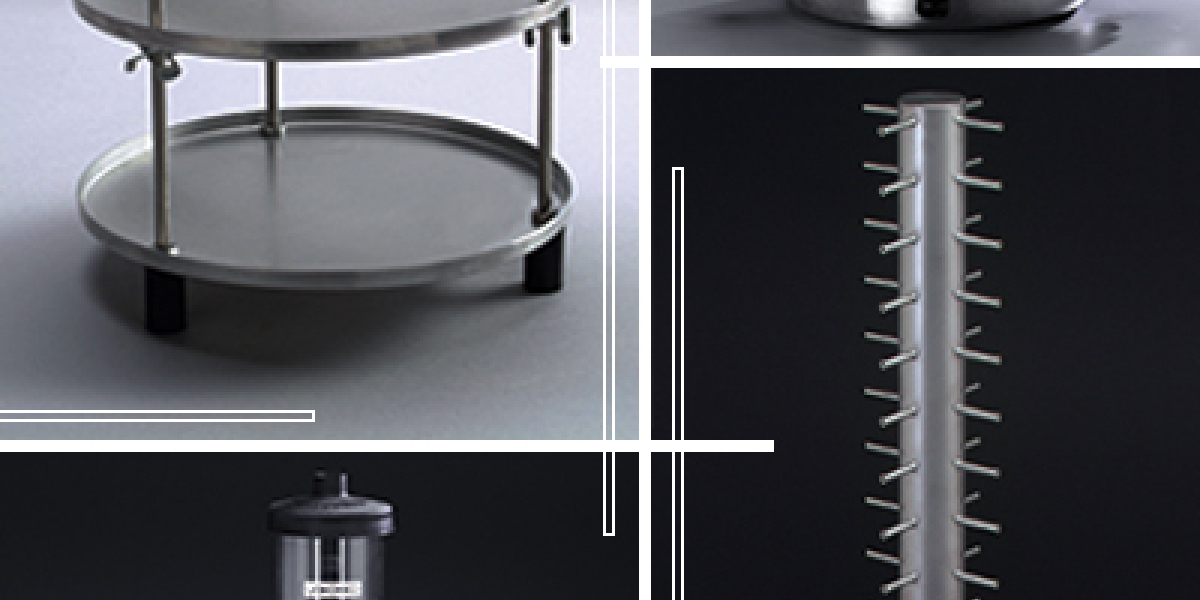

You can attach your pre-frozen flasks with adapters to a drying chamber, which is a round chamber with 12 or 16 ports. A manifold will also accept flasks but is t-shaped with 4 to 24 ports. For larger flasks, a drying chamber gives more space and optional shelves can be placed inside for drying of serum vials or bulk. The t-manifolds are better for small flasks, ampules or serum vials. Labconco ports can fit both ½” and ¾” adapters.

For serum vials or bulk samples, a tray dryer is a good method. The Triad and Stoppering Tray Dryer both have built-in refrigeration for pre-freezing, primary drying and secondary drying in one unit. When samples are dry, stoppering under vacuum or inert gas such as nitrogen can be done. This allows for long term storage without venting the dry samples to atmosphere. Another option for stoppering under vacuum is a manual stoppering chamber, which does not feature refrigeration. Pre-freezing must be done in an external freezer.

If serum vials, micro plates, petri dishes or other bulk samples need to be freeze dried without stoppering, heated or unheated product shelves fit inside a clear chamber with or without valves. After pre-freezing your sample, place them on the shelves and pull a vacuum. For freeze drying micro plates, it’s recommended to put parafilm or other barrier with vent holes on top to prevent the sample from popping out of the plate.

Large bulk sample trays such as soil, feces, and environmental samples can be dried in a Bulk Tray Dryer that offers up to 5 heated shelves. The bulk tray dryer is an economical way to freeze dry bulk samples, but does not include refrigeration. Pre-freezing must be done in an external freezer.

Ampules can be hooked directly into a port of a drying chamber or manifold using an ampule valve adapter. When freeze drying is complete, a seal torch uses oxygen and gas to flame seal the ampules under vacuum. Adding the three way adapters allows three ampules per port to increase the capacity of the freeze dryer.

A secondary trap is used to protect the vacuum pump. If solvents or acids are used, a Cascade or -105˚C freeze dryer is recommended. If you do not have a cascade model, a secondary trap can help. For trace amounts of acids or solvents, a soda acid trap or activated carbon solvent trap which may be placed between the freeze dryer and pump to trap small amounts of solvents and acids. If larger amounts are used, or if you’re experiencing melt back, a dry ice trap or liquid N2 trap are recommended. Both traps act as a second collector preventing melt back and protecting the pump.

Freeze drying requires a rotary vane pump to maintain the depth of vacuum required for successful lyophilizing. A standard rotary vane pump works well with aqueous-based solutions. For solvent and acids a hybrid or combination pump is more robust. If the solvents should bypass the collector, or if the collector is not cold enough, the vapors can go into the pump. A hybrid pump combines a rotary vane and diaphragm pump in one. The diaphragm pump pulls vapors out of the head space of the rotary vane pump preventing contamination of the oil. This leads to longer length of time between oil changes, and longer life of the pump.

If budget is a concern, the freeze dry system can be shared with a centrifugal vacuum concentrator. The concentrator hooks into a port on the freeze dryer using a ½” adapter and allows sharing of the freeze dryer collector and pump. By doing this, a second cold trap and pump are not required to operate the concentrator.

Choosing the correct accessories for your freeze dryer will make your freeze dry process more efficient and seamless.

| chevron_left | Protecting your laboratory environment with an XPert Balance Enclosure | Articles | Tuberculosis (M. tuberculosis), Containment Equipment & Laboratories | chevron_right |