What you absolutely need to know about Biological Safety Cabinets

The 3 classes of Biological Safety Cabinet

Global public health agencies define three different classifications of Biological Safety Cabinets (or BSCs).

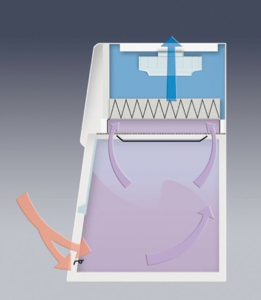

Class I

Class I BSCs are dedicated to the protection of the operator and the laboratory environment.

Class II

Class II BSCs are designed to protect the operator, the laboratory and the procedures/materials being handled in the work zone of the cabinet.

Class III

Class III BSCs (biohazard glove boxes or isolators) are meant for the most extreme of microbiological and viral materials. While providing the greatest level of protection, Class III BSCs can be very difficult to work in.

Important differences between Types of Class II Biosafety Cabinets

The bulk of cabinets used today are Class II BSCs. There are currently four recognized Types. All Class II Biosafety Cabinets provide the same level of protection against hazardous aerosols and particulates.

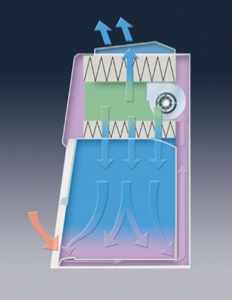

Type A

Type A cabinets can have their exhaust connected to an extraction mechanical system, allowing for the removal of the cabinet's exhaust from the laboratory environment.

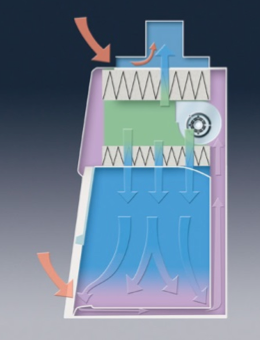

However, since all of the air moved by a Type A cabinet is mingled within a shared plenum before being redistributed through the cabinet, chemically contaminated air can be returned to wash over the work zone.

Class II A1 & A2 BSCs have the same cross section and can both be outfitted with a canopy (or thimble) to remove the exhaust from these cabinets much like a fume hood would. This should be reserved for work with odorous materials or light chemical use.

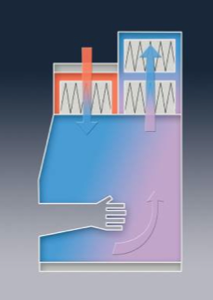

Type B

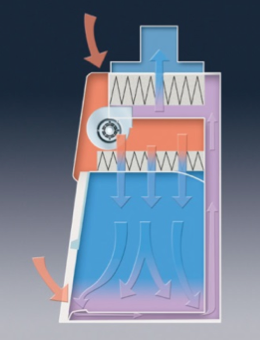

Type B cabinets provide a higher level of protection against applications involving the use of hazardous chemical vapors and radioactive materials, made so by the single pass design of airflow with direct connected exhaust.

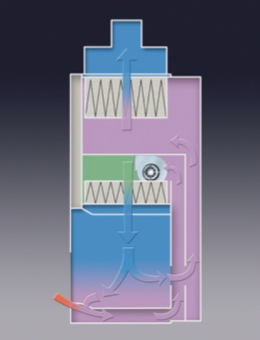

Class II, Type B1 (left) uses the "smoke split" to designate the part of the cabinet in which chemicals can be used safely. Behind the smoke split, air is moved in a single pass and directly exhausted. In front of the smoke split, the air mixes with inflow where it is then recirculated back over the work zone. Class II Type B2 (right) is a total exhaust design. Every cubic foot of air moved by the cabinet is exhausted in a single pass - like a fume hood. The entire work zone can be used for chemical hazards.

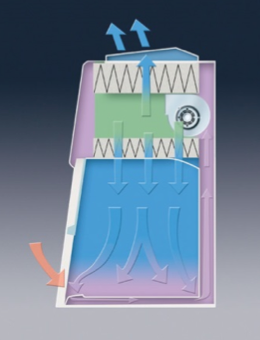

Type C1

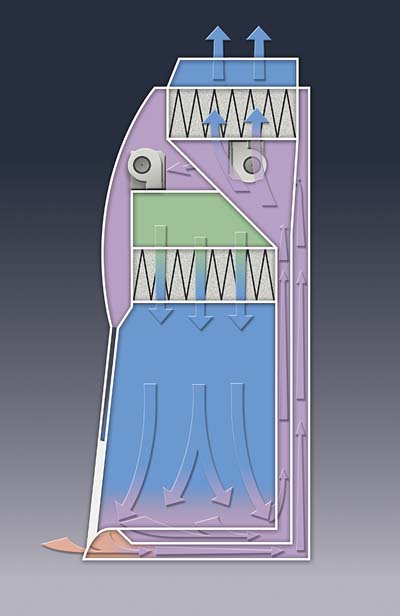

A fifth type of Class II BSC has been proposed that looks to bridge the gaps between Type A and Type B BSCs. This type of cabinet is pending final designation, but has been proposed as a Type C1. Type C1 cabinets can operate in a Type A mode or a Type B mode. They provide the highest level of protection for applications that involve the use of hazardous chemical and radioactive vapors, while solving many safety and usability issues presented by contemporary biosafety cabinets.

Like a Type A cabinet, the Type C1 can be connected to an exhaust system when protection from chemicals is required, or can be installed in a recirculating mode. When ducted, however, the Type C1 provides greater chemical safety, comparable to Type B cabinets. This is achieved through single pass airflow in a designated part of the work surface, unlike Type B1 cabinets which require special knowledge and use of the smoke-split to infer the safest place to work with chemicals.

The Class and Type of BSC you select should be primarily based on the hazards, risks and threats posed to you by the work being performed and the Biological Safety Level of the laboratory you are in.