RXPert Pharmacy Compounding Hoods & USP <800>

Almost everyone has had a prescription filled by a pharmacy. The process of filling a prescription should be familiar and simple: receive a prescription from your doctor, drive to your preferred pharmacy then hand the prescription over to the pharmacist. After a short wait you will be on your way with medicine in hand.

Almost everyone has had a prescription filled by a pharmacy. The process of filling a prescription should be familiar and simple: receive a prescription from your doctor, drive to your preferred pharmacy then hand the prescription over to the pharmacist. After a short wait you will be on your way with medicine in hand.

But what happens when a patient requires a drug dosage or drug that isn’t widely manufactured by a pharmaceutical company? Must a patient settle for an inappropriate dosage or delivery method? What if an extra milligram here or there could mean the difference between healthy and a hive outbreak?

Patients that require specialty medications can fortunately rely on compounding pharmacies.

And there are more than a few of these sites that specialize in the custom preparation of drugs. An estimate by the IACP (International Academy of Compounding Pharmacists) found that nearly 7,500 U.S. pharmacies offer compounding services.

Although largely beneficial to patients – many receive hormone replacement therapies and chemotherapies from compounding pharmacies – these specialty sites have gotten a bad rap in the last few years. In the most notable instance, a batch of sterile injections were contaminated with bacterial meningitis at New England Compounding Center, killing 64 patients.

Browse through our USP <800> compliant Double Filtered RXPert Line.

As a result, State and Federal compounding pharmacy regulators have tightened rules for compounding pharmacies. These regulations are largely derived from the United States Pharmacopeia (USP), a best-practices organization that has written numerous chapters that cover topics from storage of drugs to the proper use of water and beyond.

As a result, State and Federal compounding pharmacy regulators have tightened rules for compounding pharmacies. These regulations are largely derived from the United States Pharmacopeia (USP), a best-practices organization that has written numerous chapters that cover topics from storage of drugs to the proper use of water and beyond.

The new changes do more than just protect patients. Compounding pharmacy personnel also have to follow new regulations to protect themselves from exposure.

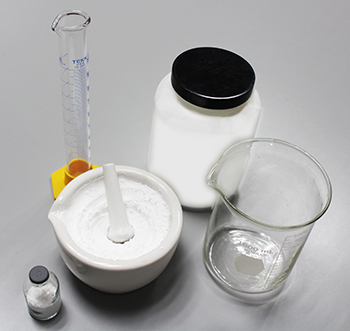

Labconco has developed a new balance enclosure, the RXPert Double Filtered Balance System, to comply with the unique, new language found in chapter <800>.

Among the new requirements is double exhaust HEPA filtration for any enclosure designed to recirculate its air back into the facility.

Based on the design of the XPert System, the Double Filtered RXPert performs well beyond USP’s double HEPA requirement by offering an industry-exclusive capability to leak-scan both HEPA filters in the unit. This assures compounders that they are working free of exposure to hazardous drugs.

The additional HEPA filtration embraces the spirit of USP <800> by providing operators with peace-of-mind and safety when handling hazardous drugs.

The pharmacy world is still dominated by major chains, but don’t be too surprised if you see an RXPert (or a variety of other Labconco equipment!) on your next visit to a compounding pharmacy.

Check out our USP <800> compliant Double Filtered RXPert Line

| chevron_left | Eliminating Contamination in Analytical Experiments | Articles | Maintaining laboratory equipment during periods of inactivity: Washers & Water Purification Systems | chevron_right |