7 questions to answer when choosing a fume hood

Choosing a fume hood can seem like a daunting task. There are so many options to choose from and so much information to gather in order to make an informed decision. But fear not, help is at hand!

First, spend a few minutes answering these questions. When you have answered all seven questions, you will have successfully established the criteria necessary for choosing a fume hood system. Then review the answers with a Labconco Application Specialist, and we will make the best product recommendations based upon your answers.

If it helps, please print this story to use as a checklist before ordering.

1. What will you be doing inside the hood?

Try to document as much as you can about the application. What chemicals are used, and how are they used? Is heat involved? What volumes of chemicals will be used at a given time? Most importantly, know the answers to the following questions:

- Do you use Perchloric Acid?

- Do you use Hydrofluoric Acid (HF)?

- Are you working with Radioisotopes and require the use of lead bricks?

2. What size of fume hood do you need?

This is a four-part question:

I. How wide do you want the fume hood to be? Labconco offers fume hoods from 30 inches wide to 16 feet wide, with many options in between.

II. Will there be equipment enclosed in the hood? If the answer is yes, then you must answer parts III and IV.

III. What are the dimensions of the equipment? This information is essential to determining how deep the hood needs to be to house your equipment.

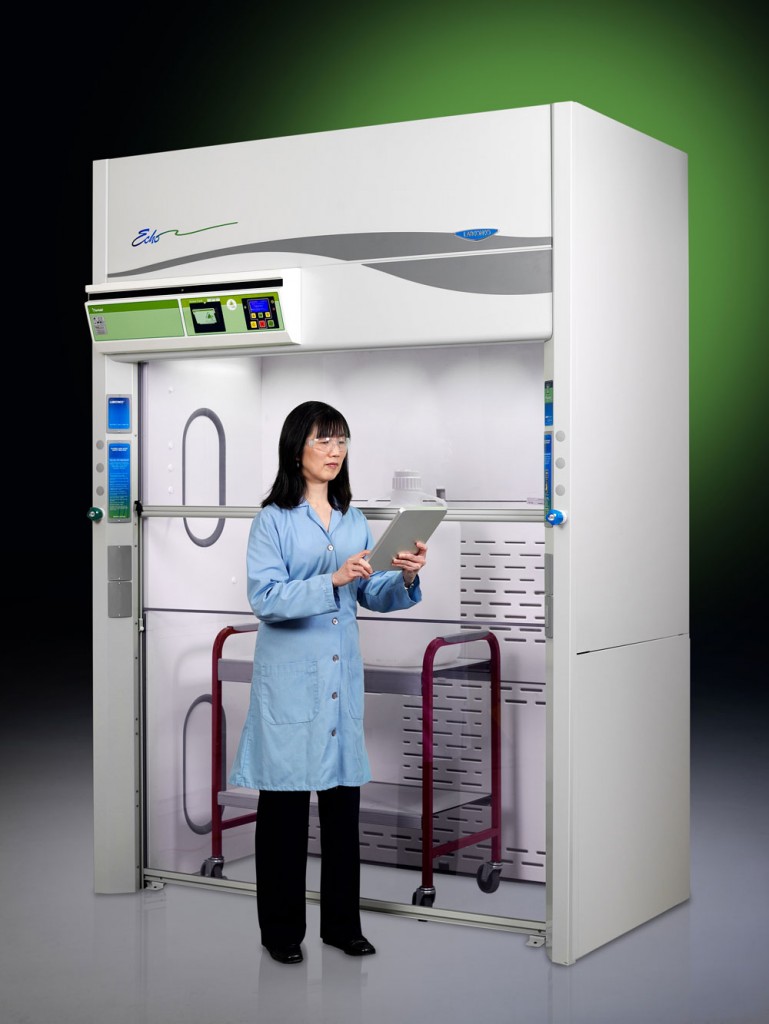

IV. Do you need a bench-top or floor mounted hood? Applications that use extra-large equipment, such as 50-gallon drums, or applications that require equipment to be wheeled into the hood via a cart would require a floor mounted hood.

3. Do you require service fixtures or other accessories in the fume hood?

These include (but are not limited to) airflow monitors, electrical outlets, compressed air, laboratory gas, vacuum and cold water fixtures. Gooseneck faucets are also available. Finally, do the fixtures need to be factory installed, or will the installer handle that at the job site by using field-installed kits?

4. What about required accessories outside of the fume hood?

- Do you need a work surface and base cabinets, or will you be using existing casework to support the hood?

- If you do need base cabinets, do you need acid storage, solvent storage or non-chemical storage?

- Do you need ductwork from the hood to the roof, or will your HVAC contractor provide it?

5. How will the fume hood be exhausted?

Every fume hood needs a blower, and it is often misconceived that a blower comes attached to a fume hood.

Will there be a dedicated blower (exhaust fan) for this hood, or will it connect to a central exhaust system?

If it connects to a central system, will it be constant volume or variable air volume?

If you already have a blower, and it is sized appropriately, you can stop right here: Contact Labconco if you'd like us to finalize your fume hood selection.

6. Do you need a built-in blower or a remotely located blower?

Built-in blowers are easier to install (and therefore less expensive), but they can be noisy and they put the ductwork under positive pressure, so they should be reserved for non-hazardous applications, short duct runs and instances where a remote blower cannot be installed (such as a mobile lab).

Remote blowers, though more complex to install, can be sized for the specific situation and keep the ductwork under negative pressure for safer operation.

7. What is the layout of the duct run?

Will the duct go directly to the roof, or does it need to make some turns before reaching the roof? What diameter of duct will be used? Once the duct penetrates the roof, a final 90-degree elbow will be needed to turn the duct horizontal, then three to five feet of straight duct is needed between the elbow and blower.

Finally, the exhaust stack should include a zero-pressure weathercap (not a gooseneck, mushroom cap or anything that would block the exhaust from discharging in a vertical, up direction), and should terminate at least 10 feet above the roofline to allow the fumes to reach the airstream and not be returned into the building’s air handling equipment.

Let the fume hood manufacturer know when you're ready to take the next step.

| chevron_left | How to freeze dry the 6 most challenging samples | Articles | Creating an adaptable lab with biosafety needs | chevron_right |